General information

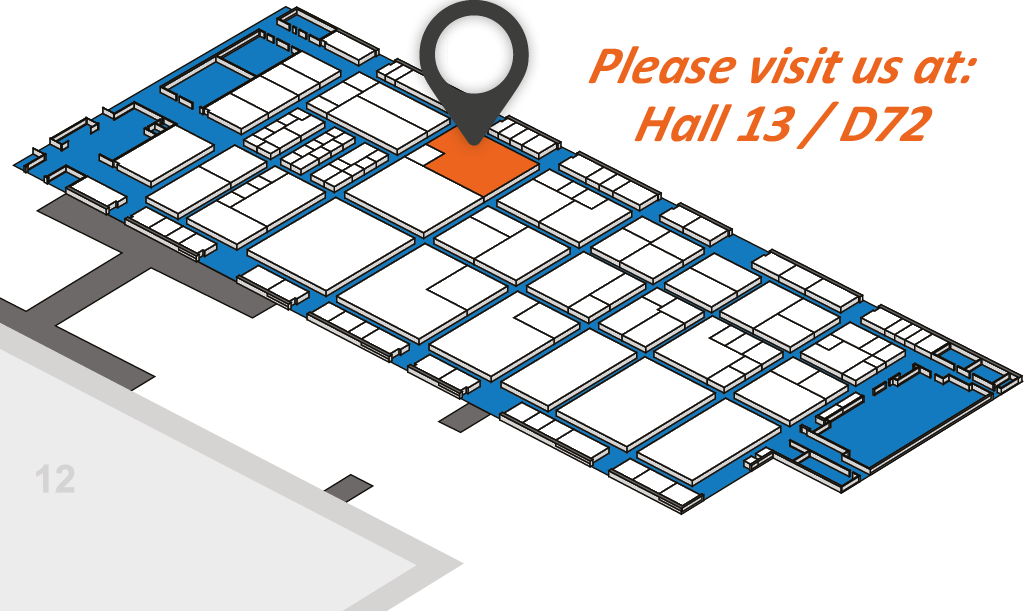

The 22nd edition of the K 2022 Plastics Fair will take place in Düsseldorf, Germany from 19 to 26 October. Stork IMM is once again pleased to be exhibiting.Stork IMM and Brink BV will once again join forces at K 2022. The theme of this year’s show will be “High Tech Holland”.

In 2019 we already introduced you to our Dutch high-tech applications but also to Dutch hospitality and solidarity within the theme "Let's Go Dutch".

This year we are stepping up our game and our technology. As Dutch companies we are very proud of the high-tech climate that the Netherlands provides.

This takes shape in our nations continuous innovation in various areas, such as wind energy, solar energy, water management, etc. Each and every one of these subjects that, in addition to the high-tech character, is also dominated by sustainability.

This year Stork IMM and Brink are presenting two joint Dutch high-tech IMM solutions, all within the theme “High Tech Holland”

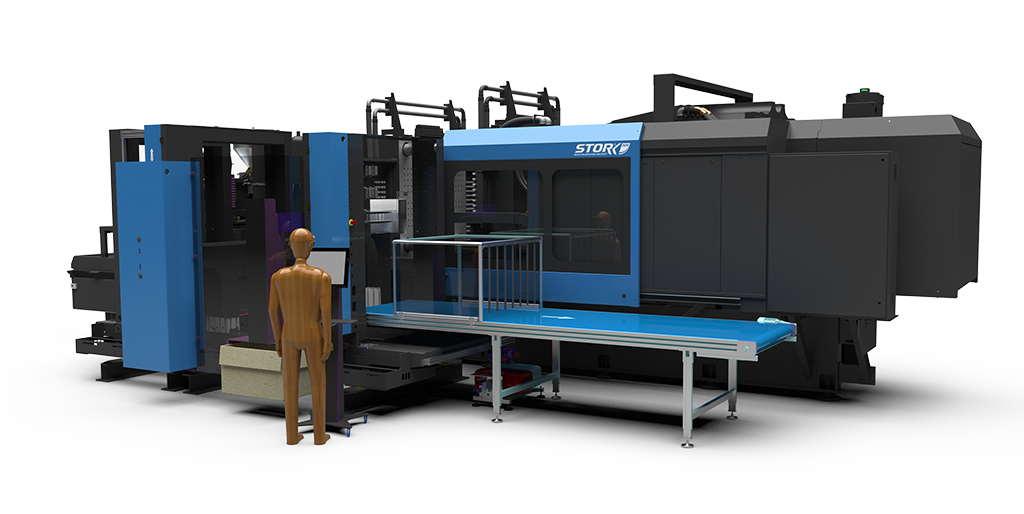

7000 kN - 8650 IMM with Electric Clamp:

On this machine, a 2-fold 10-litre bucket with an injected bracket is produced in only 6.8 seconds.With a hybrid solution, the Stork IMM injection molding machine is perfectly suited to deliver the high injection speed required for the light 2-fold 10-litre bucket. Even with these fast injection speeds, the machine is extremely reliable and stable. In addition, energy consumption is minimized wherever possible to provide best in class performance.

Due to the unique ingenuity of Stork IMM, the machine is considerably more economical than other comparable hybrid injection molding machines in the market. Depending on the electricity price, this innovation to save energy results in cost savings far above EUR 100,000 per year!

The machine is equipped with Brink side removal take-out automation and the bucket has an IML label application. The label on the bucket is designed by “made by Jessie” and is entirely dedicated to “High Tech Holland”.

The injection unit is specially designed for high speeds and maximum output. The 8650 injection unit, which is equipped with a 98 mm High Performance screw, achieves an output of 360kg/hr.

This provides an ideal combination in which you get acquainted with the speed, reliability, and durability of a Stork IMM injection molding machine.

Technical information:

- Injection speed up to 800mm/sec; something that is not yet possible with electric injection.

- Released energy is supplied back into the energy network.

- The concept, developed by Stork IMM, of several small fast valves connected in parallel, guarantees fast speeds while maintaining extremely short switching times and therefore an extremely high “shot to shot” accuracy.

- The 8650 injection unit is equipped with a 98 mm High Performance screw and achieves an output of 360kg/hr.

- The 7000 clamp has been specially developed for high-performance applications. The fast, long-stroke 5-point toggle lever system allows IML to use tall buckets. The large holm distance also makes it a popular machine for the production of crates.

4400 kN - 1450 IMM with Electrical Plasticizing

On this machine, a six-way margarine tub with IML, side take-out automation, camera control, and packaging system is presented.By means of a perfect integration of machine and equipment, a completely controlled production process is created in which the quality is optimal and the waste is minimal.

A combination of a process control that keeps the weight constant and with a hot runner control that optimizes the balance between the various cavities has been chosen.

The influence of material fluctuation is thus minimized in the process and the products are 100% uniform. This application offers an ideal solution for the use of regenerated/recylced materials without having to compromise on quality.

To enable the process control and hot runner control, the engineers at Stork IMM and Brink work closely together on a turnkey project basis. Due to software integration, the Brink robot is able to have the injection molding machine correct the hot runner temperatures and to correct emphasis and/or focus point on the basis of pressure measurement in all mold cavities.

The communication is based on OPC-UA, the latest industry standard in the field of communication between machines or with MES systems. In this concept you no longer need multiple inputs and outputs but instead only a single network cable.

The label of the margarine tub is based on a Dutch master of painting who used advanced techniques before his time with beautiful results.

Customer Services

To optimally support your production, Stork IMM has an international service team at your disposal that can support you both online and locally to implement optimizations in your production process.Based on our standard and proven basic concept and with our Dutch flexibility and specialties we are perfectly able to put together a machine that is fully tailored to your production process. With a committed team of sales managers, engineers, and software specialists, we convert your wishes into a concept that perfectly matches your needs.

NEWSLETTER

Would you like to receive our newsletter? Please subscribe!

SUBSCRIBE!ANY QUESTIONS?

Need more info about our products or our company?

PLEASE ASK HERE!