Technical Support

Remote Support – Fast Response to Malfunctions

A malfunction in your injection molding machine never happens at a convenient time. That’s why our technical support team is ready to assist you immediately, helping you get production back up and running as quickly as possible. As soon as you contact us, our specialists will ask a few targeted questions to quickly and accurately analyze the situation. When calling, always have the machine number and – if possible – an error code or a brief description of the issue at hand. The more information we have in advance, the quicker we can provide an effective solution.

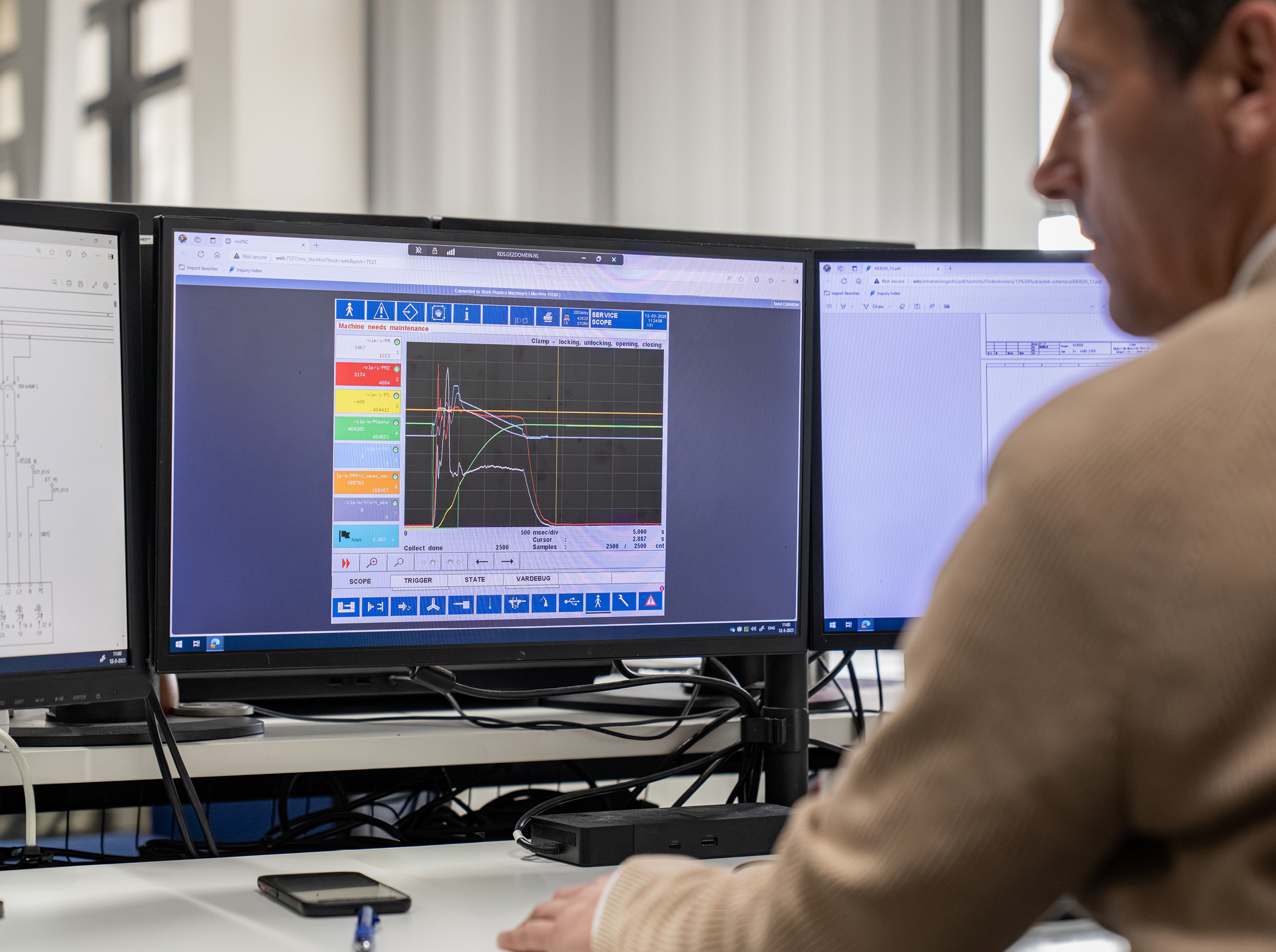

In many cases, we can perform an initial diagnosis via remote support. Thanks to modern control systems with online access, our technicians – provided the machine is connected to the network – can remotely view the software, check settings, and read error messages. Often, adjustments or restarts can be carried out remotely, allowing you to be operational again in no time. This saves both valuable time and call-out costs.

Local Service – On-Site When Needed

If the issue cannot be resolved remotely, or if a physical component needs replacement, our field service engineers are at your disposal. We have an extensive service network, with our own technicians as well as qualified partners in the Netherlands, Germany, the United Kingdom, Poland, France, the United States, and Australia. This enables us to respond quickly and offer local support whenever and wherever it’s needed. Whether it’s an emergency, a scheduled intervention, or a complex mechanical repair – you can rely on fast and professional service, worldwide.

Technical Support

tips & tricks

Tips for Optimal Machine Performance

Ensure a long service life and get the most out of your machine.