Our History

For over 150 years, Stork IMM has evolved from a pioneering machine factory into a global leader in high-performance injection molding. Our history is defined by continuous innovation, adaptability, and a strong commitment to customer-focused solutions.

The Origins of Stork IMM

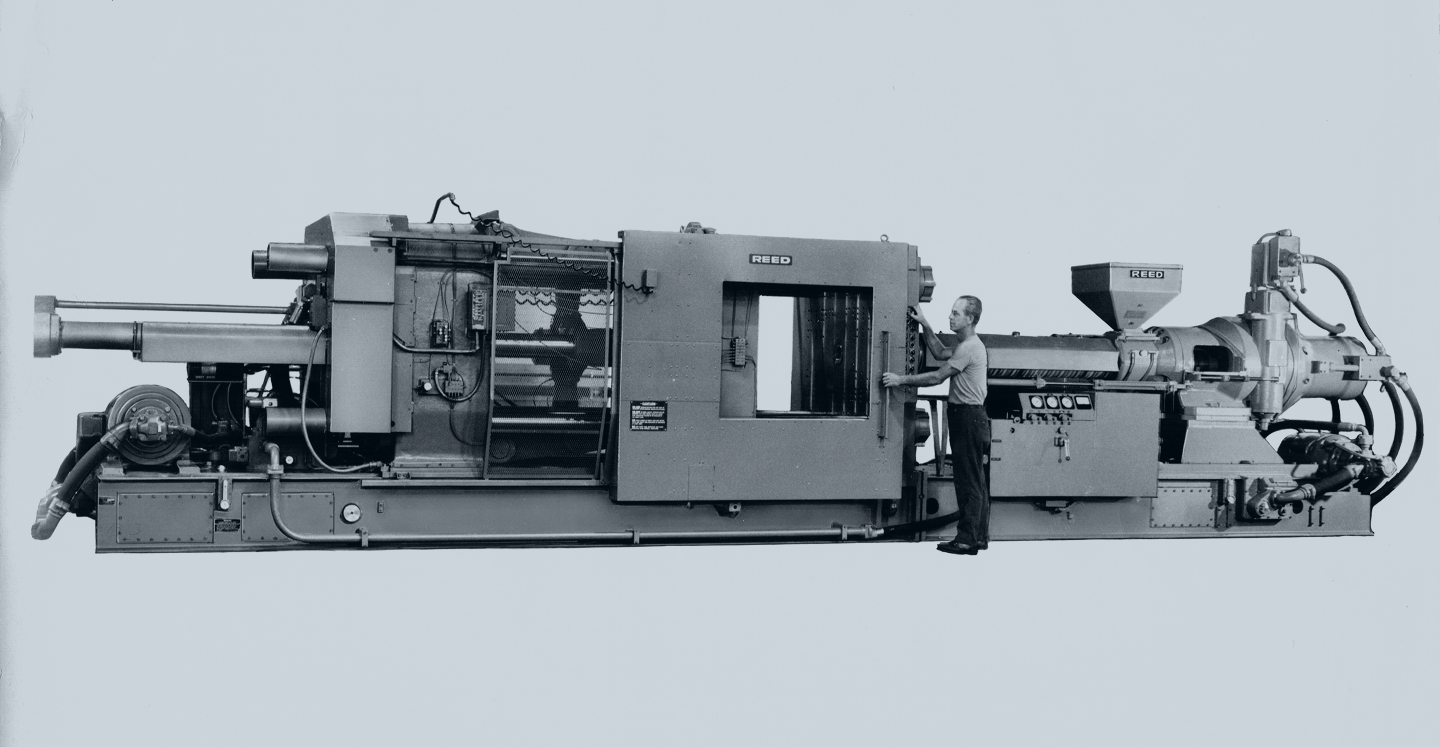

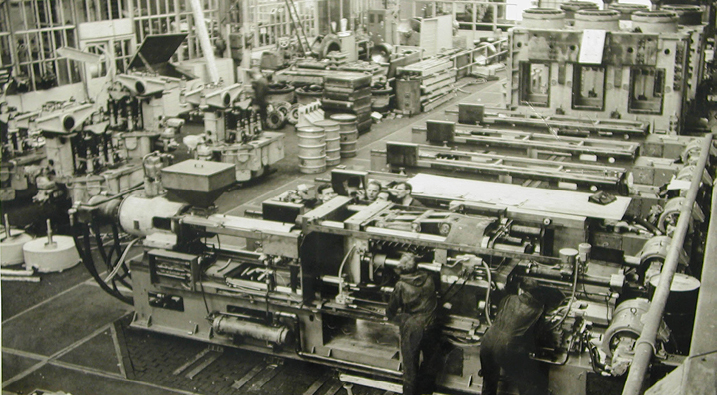

Stork IMM has its roots in the Royal Machine Factory Gebr. Stork & Co, founded in 1868 in Hengelo. The company gained renown for building robust steam engines, diesel engines, and pumps. Due to increasing competition in the marine engine market, new opportunities were sought. The focus shifted to plastics technology, leading to a partnership with the American company Reed Corp. In 1968, the first injection moulding machine was delivered under license, marking the birth of Stork Plastics Processing Machinery B.V. (SPPM).

Growth and Innovation

The first Stork injection moulding machines, based on American designs, were a success. In 1974, the TDS series was launched, but rising costs and technological lag prompted a reinvention. In 1979, SPPM was renamed Stork Plastics Machinery B.V. (SPM). The ST series was developed, focusing on customer-specific features and advanced control systems. By the late 1980s, the aging ST series led to the development of the SX series, which would form the basis for future innovations.

Challenges and Developments

In 1993, economic decline led to a reorganization, but Stork quickly recovered thanks to the modular design of the SX series. The SX18000-19000, the largest machine at the time, was developed. In the late 1990s, Stork NV sold part of its shares, making the company no longer a fully owned Stork subsidiary. In 2006, the company moved to a new location. In 2013, the name was changed to Stork IMM, aligning better internationally with the focus on injection moulding machines. At the same time, the corporate identity was refreshed, and the company continued to grow with four specialized machine lines: Food-line, Pail-line, Crate-line, and Pot-line.

Stork IMM Today

Stork IMM continues to innovate and distinguish itself through speed, reliability, and customer-focused solutions. With a strong emphasis on packaging solutions such as buckets and food containers, Stork IMM produces machines ranging from 2000 to 20000 kN. Thanks to advanced controls and robust construction, Stork IMM is known as a manufacturer of high-quality, high-speed injection moulding machines. Its global presence is expanding, with agencies in Europe, Australia, and North America. Through continuous innovation and customer orientation, Stork IMM remains a leading player in the industry.