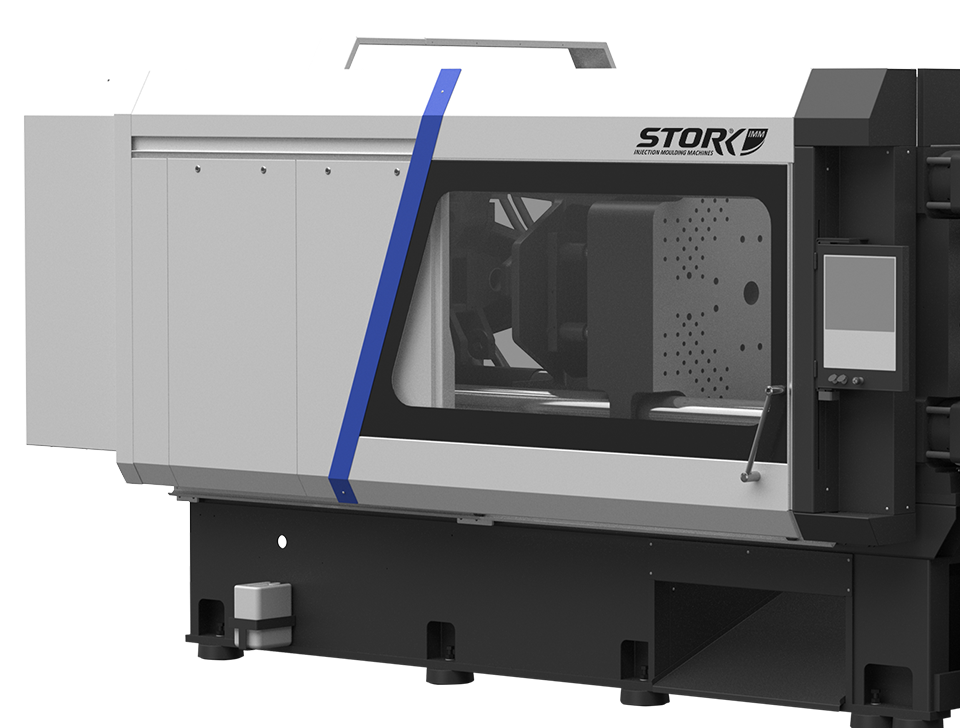

Full Hybrid Injection Moulding Machines

Injection Moulding Machines with electric clamping, hydraulic injection, and electric dosing

We are happy to help.

Full Hybrid Range

Maximum Performance, Minimal Energy

The Full Hybrid from Stork IMM combines the best of both worlds: electric clamping, hydraulic injection, and electric dosing. This hybrid concept has been specially developed for applications where speed, precision, and efficiency are crucial – such as the production of buckets, flower pots, and thin-walled food packaging. It is also perfectly suited for producing logistics crates.

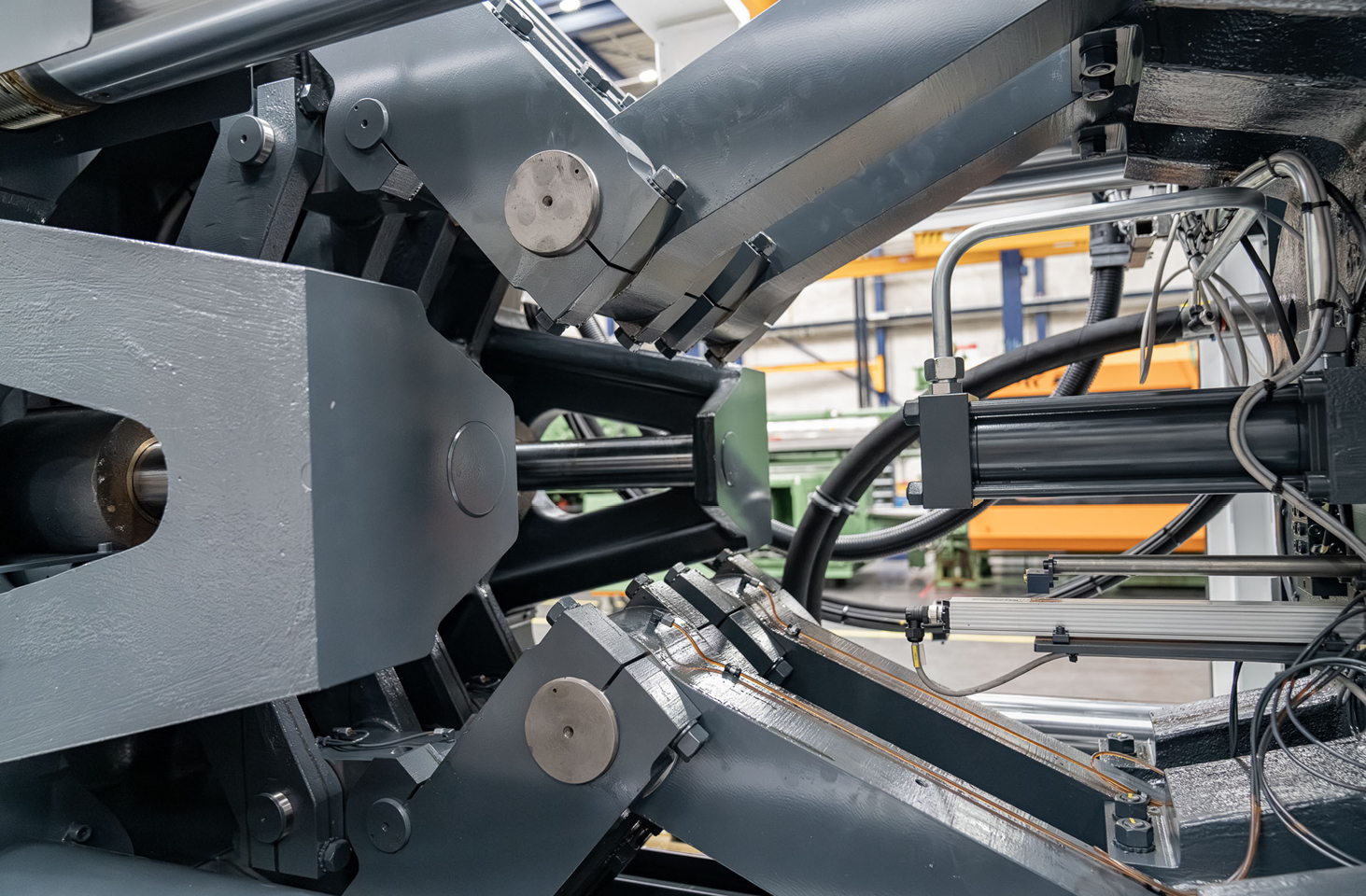

Thanks to the electric clamp, ultra-fast movements are possible with extremely low energy consumption. During braking, energy is regenerated and reused, making the machine even more efficient. The robust rack-and-pinion drive, using a single motor for both movement and locking, delivers powerful and stable clamping force. This smart configuration ensures that the Full Hybrid is exceptionally sustainable in use.

The hydraulic injection unit is finely tuned for speed and control. A smaller valve size shortens the response time, resulting in precise injection control. For even higher filling speed requirements, the machine can optionally be equipped with a three-valve injection block – ideal for thin-walled products and high-cavity molds. The accumulator pressure is adjusted to the actual required injection pressure, which reduces pressure loss in the system and lowers energy consumption.

Mechanically, the Full Hybrid is built for long life and high precision. The recently updated BSP version offers even greater static and dynamic stability, reducing deflection under high clamping forces. This results in less mould wear and a more effective clamping process.

With short cycle times, high injection pressure, and excellent energy efficiency, the Stork IMM Full Hybrid is the ideal solution for demanding production processes involving multi-cavity moulds and thin-walled products. Ready for 24/7 performance, with a focus on quality, sustainability, and profitability.

With clamping units from 200 to 1400 tons and various injection units – with screw diameters from 45 to 150 mm – Stork IMM offers tailor-made solutions that precisely meet application needs.

packed with performance

Stork IMM Full Hybrid

Why choose the Stork IMM Full Hybrid?

Maximum speed with minimal energy

The Stork IMM Full Hybrid is designed for top performance with unmatched cycle times. Its advanced technology ensures fast production without unnecessary energy waste. You get high-speed output while significantly reducing operational costs

Precise, powerful injection

With high injection pressure and refined control, it delivers consistent, top-quality results. Even the most demanding moulds are handled with accuracy and care. This means fewer rejects and a smoother production process every time.

Robust and durable design

Built to handle intensive use, the Full Hybrid stands up to the toughest conditions. Its components are engineered for reliability and long-term operation. This makes it a smart investment with minimal downtime and maintenance.

Years of experience in machine building

Support and service for maximum productivity

Installed injection moulding machines worldwide

fully customized

Our Approach

A Stork IMM injection moulding machine is always fully tailored to your production process. Depending on the application, our team of specialists will work with you to define the technical specifications. We then create a 3D model and review the configuration together to ensure it fully meets your expectations. In the next phase, the engineering team starts developing the machine, and our supply chain is involved early to minimize lead times. Once all parts are in, our assembly team gets to work. Your machine is thoroughly tested, and after a successful FAT, our service team will commission it. Once your machine is up and running, it is added to our installed base, and our service team remains available at all times to provide the support you need.To get the most out of your machine, we offer a variety of training programs for operators and technical staff.We also recommend a maintenance contract to keep your machine in optimal condition.

High-Performance

Aligned with your production process

Maximum performance, minimal costs, and a sustainable future

Maximum efficiency

Our injection moulding machines are designed for top performance, with maximum uptime and production capacity.

Cost-efficient

Optimize your production process and reduce operational costs with our sustainable and efficient technologies.

Flexible deployment

Our solutions are tailored to your specific production needs, with customizable features for every industry.