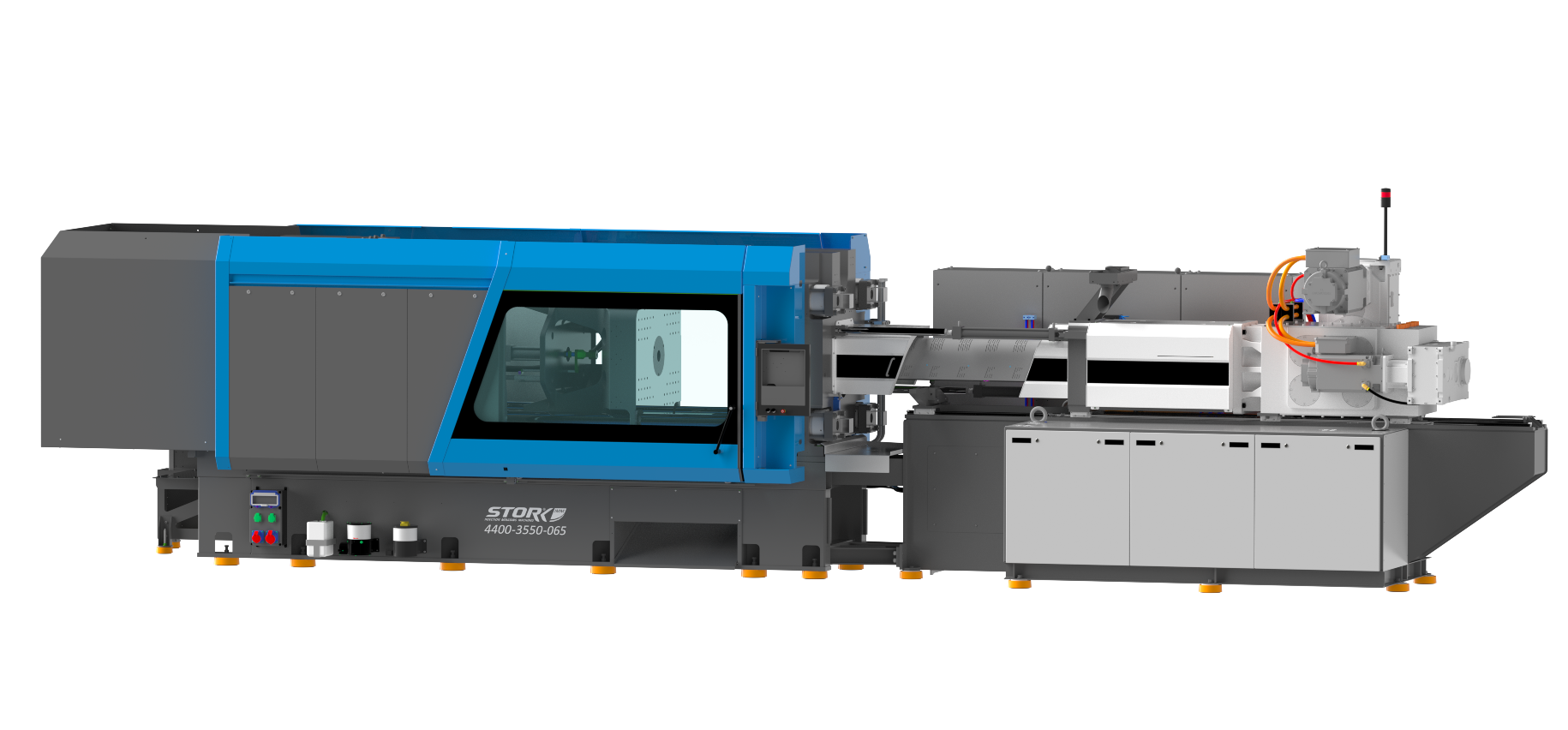

All Electric Injection Moulding Machines

Injection Moulding Machines with electric clamping, injection and dosing

We are happy to help.

All Electric Range

Sustainable Power for High-Performance Packaging Production

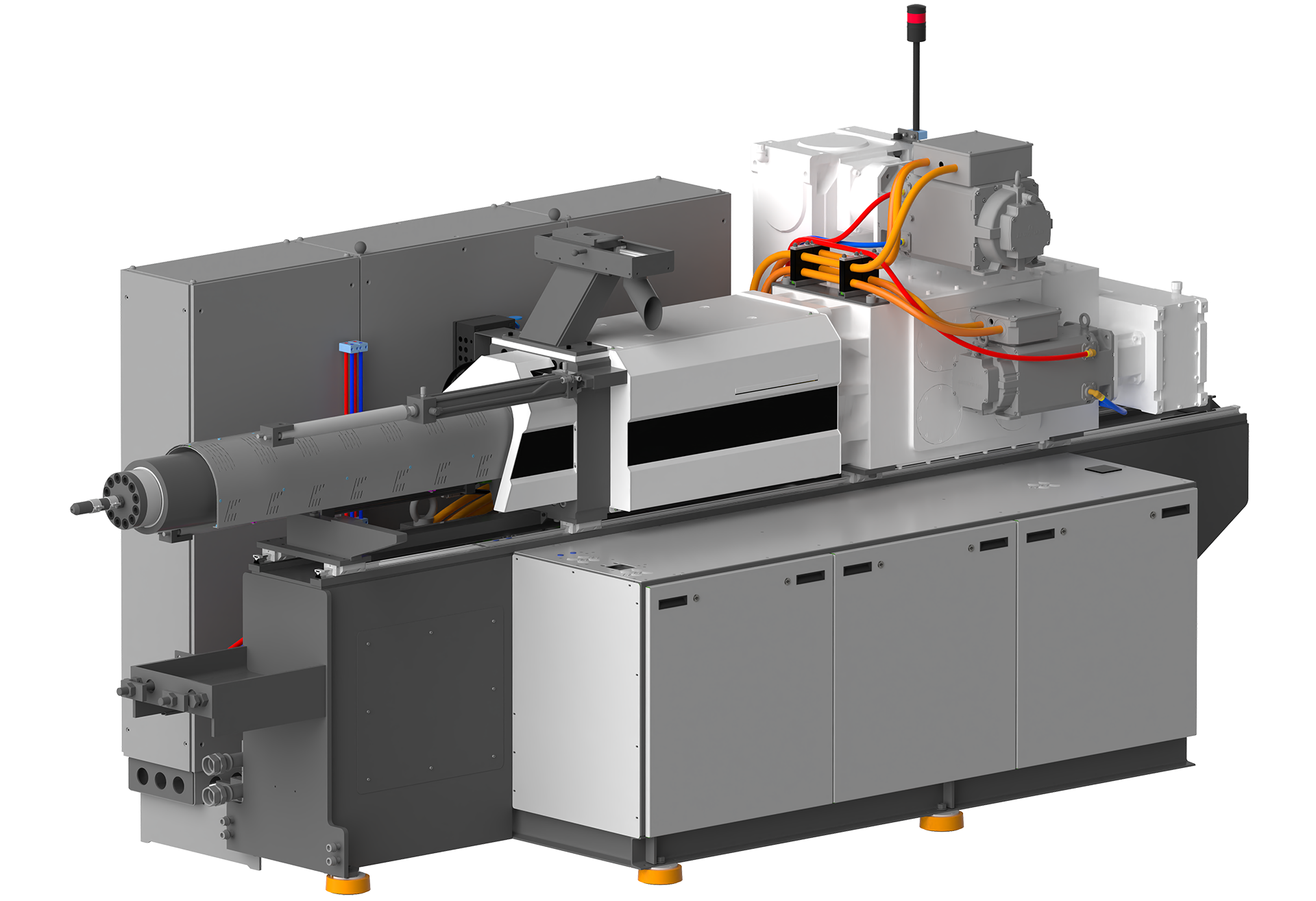

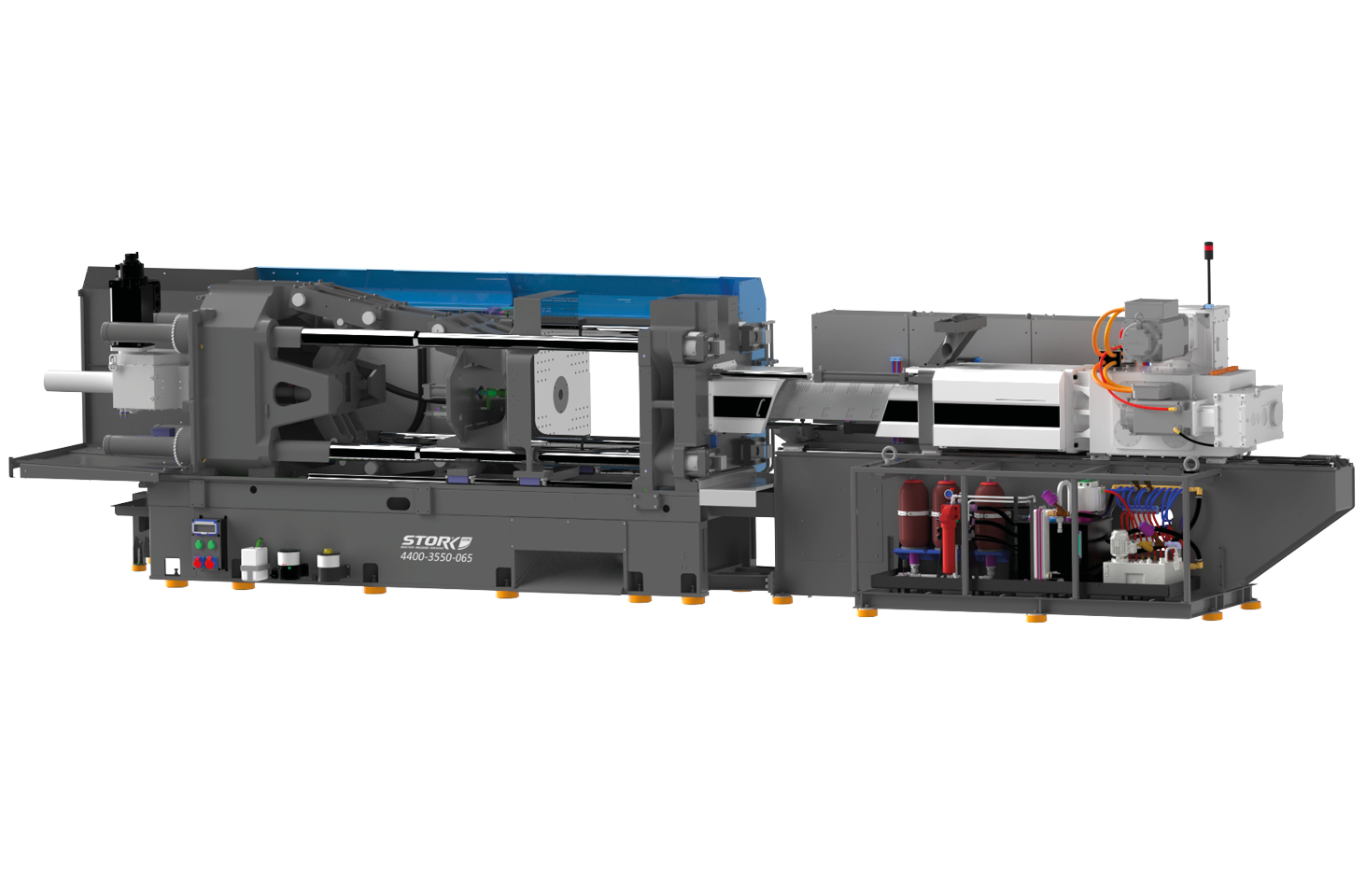

The All Electric from Stork IMM has been developed to combine maximum performance with minimal environmental impact. These fully electric injection moulding machines are ideal for producing thin-walled food packaging, flower pots, buckets, and lids. They deliver the same output and reliability as Stork IMMs proven hybrid models – but with even lower energy consumption.

The machines, among others, feature a heavy-duty rack-and-pinion drive system for the clamping movement. This system is extremely rigid, efficient, and wear-resistant, making the All Electric series perfectly suited for high-cavity applications and short cycle times.

The electric drive enables up to 15% energy savings compared to similar hybrid models. In addition, braking energy is regenerated and fed back into the customer’s power grid, further reducing total energy consumption. Maintenance is also a strong point: less mechanical wear means less downtime and lower service costs.

With clamping units ranging from 250 to 700 tons and various injection units – including screw diameters from 52 to 84 mm – Stork IMM offers tailored solutions that precisely match the application requirements.

With our All Electric range, Stork IMM emphasizes its commitment to technology that not only performs but also aligns with the ambitions of a circular economy.

packed with performance

Stork IMM All Electric

Why choose the Stork IMM All Electric?

Sustainability with measurable energy savings

Our all-electric machine consumes significantly less energy. This reduces both operational costs and environmental impact. A smart choice for forward-thinking, sustainable production.

Power and precision for demanding applications

Ideal for thin-walled packaging and industrial components. Highly accurate injection means less waste and fewer rejects. Get the highest quality and efficiency with every shot.

Reliability and long service life

Robust electric drive ensures long-term, stable performance. Less maintenance equals lower costs and more uptime. A future-proof investment that lasts.

Years of experience in machine building

Support and service for maximum productivity

Installed injection moulding machines worldwide

fully customized

Our Approach

A Stork IMM injection moulding machine is always fully tailored to your production process. Depending on the application, our team of specialists will work with you to define the technical specifications. We then create a 3D model and review the configuration together to ensure it fully meets your expectations. In the next phase, the engineering team starts developing the machine, and our supply chain is involved early to minimize lead times. Once all parts are in, our assembly team gets to work. Your machine is thoroughly tested, and after a successful FAT, our service team will commission it. Once your machine is up and running, it is added to our installed base, and our service team remains available at all times to provide the support you need.To get the most out of your machine, we offer a variety of training programs for operators and technical staff.We also recommend a maintenance contract to keep your machine in optimal condition.

High-Performance

Aligned with your production process

Maximum performance, minimal costs, and a sustainable future

Maximum efficiency

Our injection moulding machines are designed for top performance, with maximum uptime and production capacity.

Cost-efficient

Optimize your production process and reduce operational costs with our sustainable and efficient technologies.

Flexible deployment

Our solutions are tailored to your specific production needs, with customizable features for every industry.