smart customizations

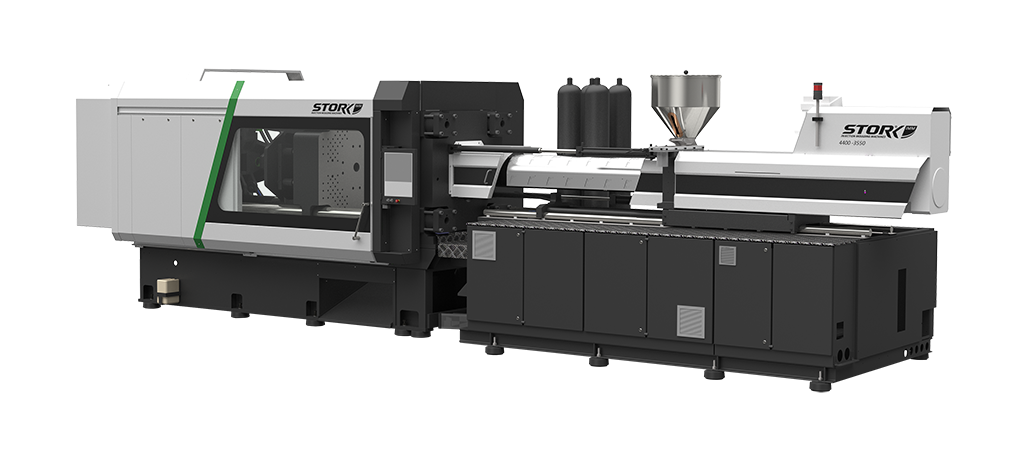

Injection moulding machines for flower pot production

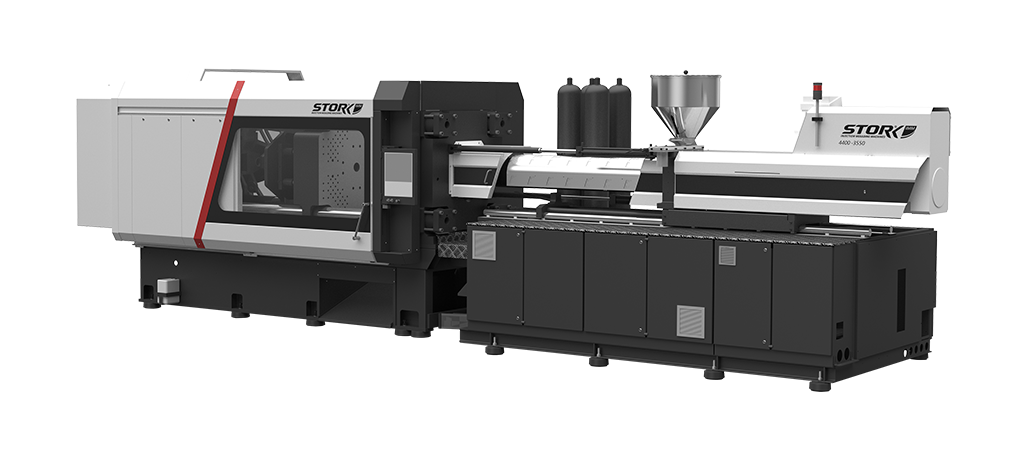

Stork IMM offers a specialised injection moulding line for high-volume flower pot production.

The machines are built for fast cycles, consistent quality, and low cost per unit.

They ensure stable demoulding and even clamping force—ideal for multi-cavity or stack moulds.

Recycled materials are handled with precision, guaranteeing consistent wall thickness and appearance.

This makes them a robust, energy-efficient, and reliable solution for modern pot production.

application

Pots

The production of plastic flower pots is a game of speed, durability, and process control. In this application, everything revolves around high volumes at the lowest possible cost per unit. At the same time, the end product must be consistently high quality: pots must be sturdy, dimensionally stable, and visually appealing – especially for consumer products. They must stack well, include drainage holes, and withstand transport and various (outdoor) conditions. A key feature of flower pot production is the use of recycled materials. This demands a machine that can handle fluctuations in melt quality and MFI (Melt Flow Index) without causing inconsistencies in wall thickness or product shape. A stable plasticizing process and reliable injection are crucial, especially for deep pot designs or high-cavity moulds.

Part removal must be smooth and controlled – delays or blockages in the cycle lead directly to production downtime. Moreover, flower pots are often produced in multi-cavity or stack moulds, requiring a powerful machine setup and precise clamping force distribution to ensure consistent quality across all parts. The visual finish – color, surface texture, and wall thickness – must remain uniform, even during long production runs. Process stability plays a key role here.

maximum output, minimal disruption

Pots

Successful flower pot production demands a machine that delivers high output, handles recycled materials exceptionally well, and provides a reliable, predictable process – even with deep products and large production series. A stable foundation is essential to stay competitive in a high-volume market where perfect quality is a must.

high-performance

Aligned with your production process

Maximum performance, minimal costs, and a sustainable future

Maximum efficiency

Our injection moulding machines are designed for top performance, with maximum uptime and production capacity.

Cost-efficient

Optimize your production process and reduce operational costs with our sustainable and efficient technologies.

Flexible deployment

Our solutions are tailored to your specific production needs, with customizable features for every industry.

Years of experience in machine building

Support and service for maximum productivity

Installed injection moulding machines worldwide

support & service

Our Service and Support

At Stork IMM, we are here to assist you at every stage of the process. From initial installation to ongoing support, we offer complete services to ensure your injection molding machines deliver optimal performance.

Homeour partners

Partners with performance

Quotation

Request your quote now via our form.

We will contact you within a few business days. If you have any questions in the meantime, please call: +31 (0) 74 240 5000.

Pot-Line