smart customizations

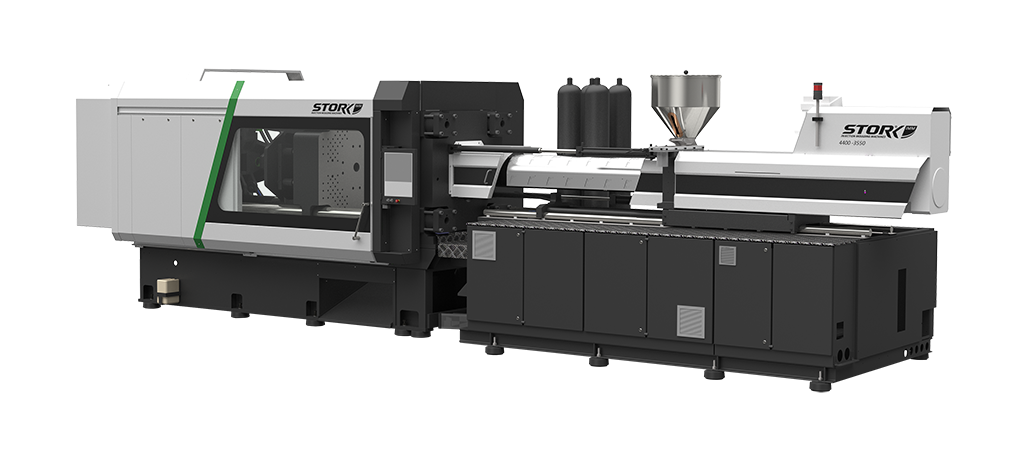

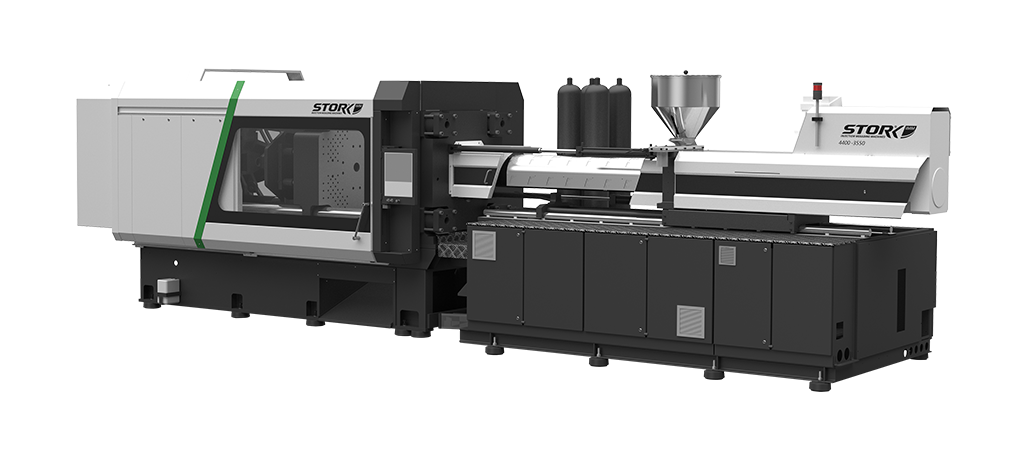

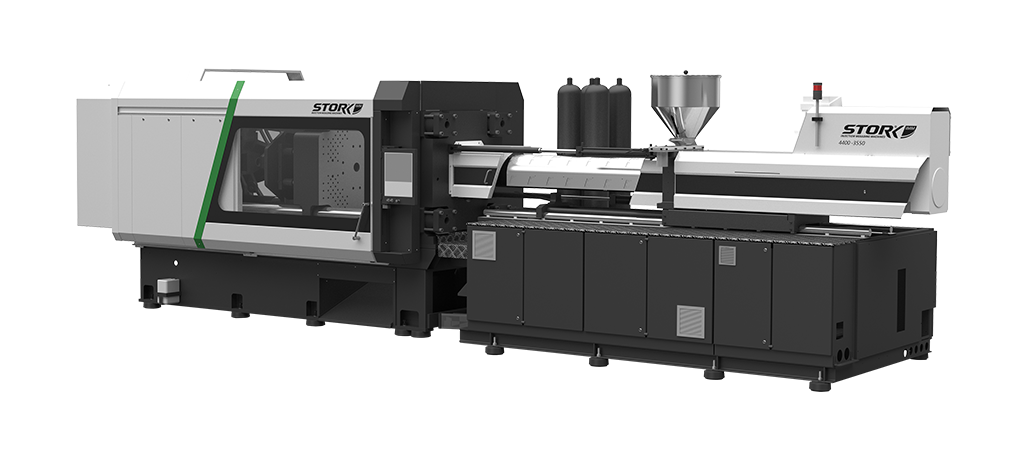

Injection moulding machines for the production of thin-walled food packaging

Stork IMM offers a high-speed injection moulding platform tailored for food packaging production. The machines combine precision, hygiene, and reliability for thin-walled, high-quality products. Optional food-safe lubrication systems prevent contamination and support long-term performance. Strong support for multi-cavity moulds enables efficient, high-output production.

This makes them the ideal choice for 24/7 food packaging in strict hygienic environments.

application

Food Packaging

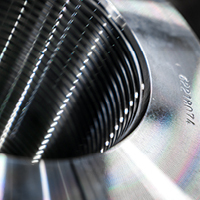

The production of plastic packaging for food – such as yogurt cups, margarine tubs, or transparent trays – requires an extremely fast and precise injection molding process. Cycle times are extremely short, wall thicknesses often minimal, and tolerances tight. At the same time, hygiene requirements are high: every part of the process must meet food safety standards.

Successful production starts with a machine featuring very high injection speed, short cooling and filling times, and maximum dimensional stability. Even with wall thicknesses of just a few tenths of a millimeter, the end product must come out of the mold tight and deformation-free – in high quantities and without waste.

Process repeatability is crucial. Lightweight designs leave little room for error: a fraction too much material or a deviation in cooling balance can already lead to defective or poorly stackable products. A clean working area and closed lubrication systems are essential to prevent contamination and ensure consistent quality.

In short: thin-walled food packaging requires a machine that effortlessly combines hygiene, speed, and precision – for maximum output and product safety.

high speed, precision, and hygiene

Food Packaging

Thin-walled food packaging requires a machine that effortlessly combines hygiene, speed, and precision – for maximum output and product safety.

high-performance

Aligned with your production process

Maximum performance, minimal costs, and a sustainable future

Maximum efficiency

Our injection moulding machines are designed for top performance, with maximum uptime and production capacity.

Cost-efficient

Optimize your production process and reduce operational costs with our sustainable and efficient technologies.

Flexible deployment

Our solutions are tailored to your specific production needs, with customizable features for every industry.

Years of experience in machine building

Support and service for maximum productivity

Installed injection moulding machines worldwide

support & service

Our Service and Support

At Stork IMM, we are here to assist you at every stage of the process. From initial installation to ongoing support, we offer complete services to ensure your injection molding machines deliver optimal performance.

View our servicesour partners

Partners with performance

Quotation

Request your quote now via our form.

We will contact you within a few business days. If you have any questions in the meantime, please call: +31 (0) 74 240 5000.

Premium (machines)

Food-Line