Applications

Stork IMM specializes in building high-performance injection moulding machines for thin-walled packaging. Based on our many years of experience in this market, we have developed a range of advanced options for specific applications such as pails, flower pots, food packaging, and crates. These form the foundation for configuring an injection moulding machine that perfectly fits your production process. By selecting the options relevant to your needs, you can create the ideal machine for optimal production and strengthen your competitive position. Choosing a Stork IMM injection moulding machine means choosing the lowest total cost of ownership.

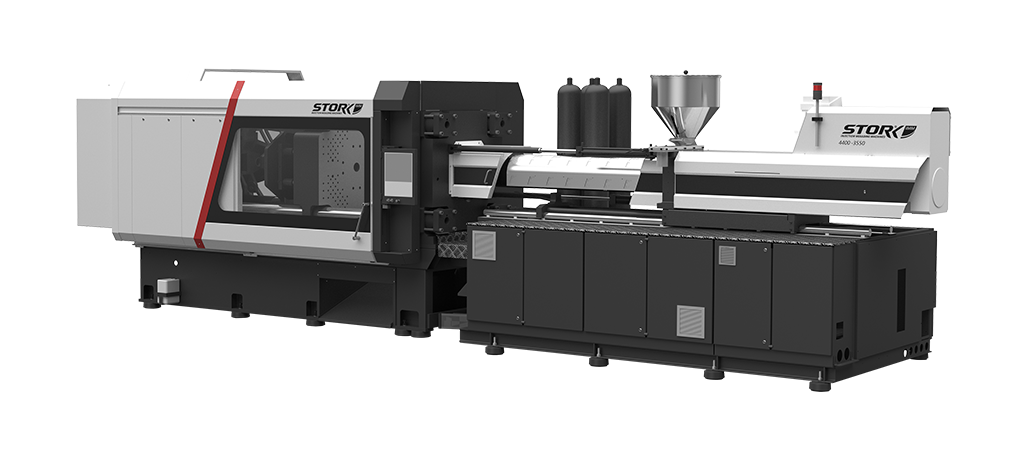

Pail-Line

The Pail-Line from Stork IMM is fully focused on high-performance injection moulding machines for the production of pails and lids. The wide range of developed options is designed to ensure maximum uptime, minimal energy consumption, and extremely short cycle times. We also offer features to support IML, moulded-in handles, perfect colouring, and food-grade pails and lids.

Thanks to our powerful injection technology and stable ejection systems, deeper pails and multi-cavity mould setups are easy to produce. Ideal for manufacturers aiming for maximum output and consistent product quality.

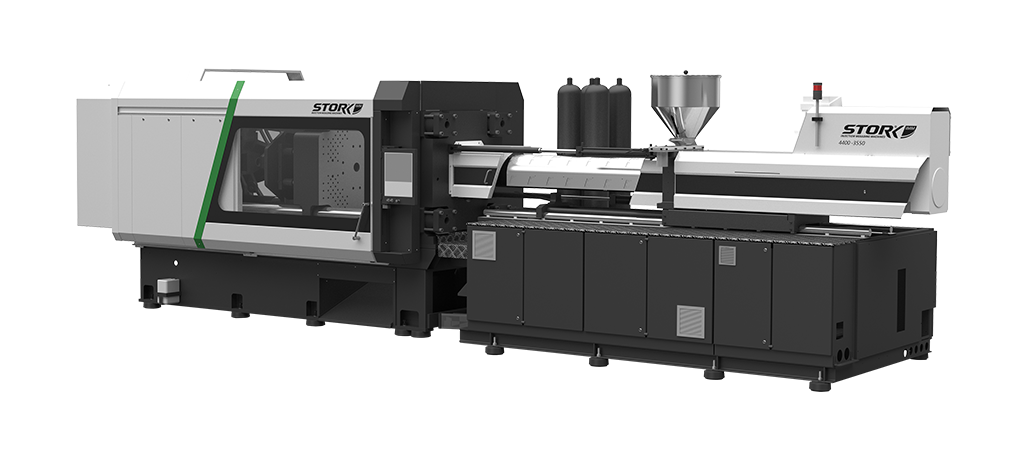

Pot-Line

The Pot-Line from Stork IMM is fully focused on high-performance injection moulding machines for the production of flower pots. The various well-developed options are aimed at achieving maximum uptime, minimal energy use, and extremely short cycle times. Our solutions ensure optimal operational protection and homogeneous melting of recyclate.

We also offer options that contribute to an even more stable production process. Perfect for applications involving recyclate or high-cavity moulds—without compromising on dimensional stability or visual appeal.

Food-Line

The Food-Line from Stork IMM is fully focused on high-performance injection moulding machines for the production of thin-walled food packaging. The wide range of developed options ensures maximum uptime, extremely high injection speeds, and optimal hygiene. We also offer solutions for multi-cavity and stack moulds, as well as PET processing.

Our systems ensure consistent wall thickness and short cycle times, even for transparent packaging and high volumes. Ideally suited for producers competing on speed, precision, and food safety.

Crate-Line

The Crate-Line from Stork IMM is fully focused on high-performance injection moulding machines for the production of crates. The various developed options are aimed at maximum uptime, minimal energy consumption, extremely short cycle times, and perfect colouring.

We also offer options such as mould protection systems, low pressure drop, start-up programs, and the processing of low-MFI materials. Even with robust products featuring thicker walls or recycled content, we guarantee a reliable and predictable process—ideal for those focused on sustainable, error-free mass production of logistical carriers.